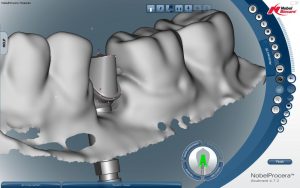

Digital screen shot of an implant abutment ready to send to be milled in titanium

Digital Impact in Dentistry

By: Steve Killian, CDT

Change is Difficult

It’s a brave new world with all of the digital changes we experience in our daily lives. The changes seem to be coming at us at a geometric rate of growth. It simply is overwhelming at times. Oftentimes we look to our kids to help us keep up with the switch to Windows 10 or to help us figure out how to thank a restaurant for a great experience on Yelp. I certainly do.

But dentistry is different in that change has historically come slowly. Hand dexterity is a premium skill and learning to use the hand tools and small drills takes time and practice to become proficient.

Many of us have experiences at the dentist that goes well beyond the usual cleaning and x-rays, unfortunately. Some of you may have already experienced the new digital imaged x-rays. The time to bring the image to the monitor chairside is massively reduced. The computer transforms the x-ray in seconds instead of minutes and the image is clearer than film x-rays and is visible on a large monitor instead of off tiny films. If the digital image comes out poorly, it is easy to quickly take another image at no extra cost and in virtually no time.

But many of us need to get fillings, crowns, bridges, root form implants with crowns, orthodontics, dentures, etc. The traditional methods of restoration were as I mentioned best performed by a very experienced dentist carefully practicing precise hand techniques. But now that is changing exponentially with the digital world.

Dentists are Beginning to Make the Change to Digital Methods

CAD/CAM dental machinery in a highly modern dental laboratory, with disc for crowns and fixed partial dentures.

General Practitioners, Oral Surgeons, Periodontists and Orthodontists must partner with highly skilled and experienced dental technicians through the digital change and the rest of the dental community are gauging their colleague’s success very carefully. With that the traditional dental laboratory is changing at an exponential rate to offer inlays, veneers, crowns, bridges, implant abutments, dentures, implant drill guides, etc. through Cad Cam design and milling. World and national economic change, off shore competition and a new range of modern restorative materials are helping to accelerate the change to digital methods of fabrication in the modern dental laboratory. Because of fast and continuing advances in digital technology and materials, now more than ever, dentists depend on the laboratories’ expertise to lead them in treatment planning and restorative materials selection.

Chair Side Intra-Oral Impression Scanning and Cad Cam Laboratory Design and Milling

Dentist and Patient with an Intra-Oral Impression Scanner

While little has changed in appearance at the dentist’s chair side you will notice that the new digitally savvy practitioner will have a new “Magic Wand” and will have a lack of traditional impression trays and “Goop” to fill them with. Those of us who have had to suffer through the traditional goopy impressioning process are now wowed by the new technology with these intra-oral impression scanners. While looking like a large electric toothbrush without the bristles, the Intra-Oral Impression Scanner is able to take digital 3-D images of the mouth after the dentist has prepared or prescribed inlays, veneers, crowns, bridges, implant abutments/crowns, dentures, orthodontics, etc. These images are extremely accurate to within 3 millimicrons over a span of the oral arch. The images are uploaded to a laboratory anywhere in the world of the dentist’s choosing. Within minutes the images are received at the laboratory where a skilled technician can design the restoration on sophisticated software. The design is sent to a mill in the lab for preliminary creation of the restoration. Any number of materials such as Zirconia, High Strength Ceramics, Wax for casting later into metal or high strength ceramic, Acrylic for temporary restorations, Acrylic for Dentures, Printed or Milled models, Drill Guides, etc.

Split Files; Models and Drill Guides

A milled plastic model, a gold anodized titanium implant abutment with gold screw and a natural tooth colored molar crown of zirconia all to fit precisely in the mouth….all from one intra-oral digital scan.

While the restorations are being made the original intra-oral scan file can be split for model making. The model is a full reproduction of the mouth parts that were scanned. The model can be milled out of a block of suitable plastic material or it can be printed with a 3-D printer. Skilled laboratory technicians use the models to verify fit, function, shade and finish by traditional hand methods. Other models may be combined with Cone Beam Computer Tomography (3-D X-Rays) to plan Fully Guided Surgery which allows for precise root form implant placement within bone, nerve, adjacent teeth and sinus confines. Once planned and approved on the computer, a precision drill guide can be printed to aid in precise implant placement during surgery.

Digital Precision, New Restorative Materials, Precision Fit, Bio-Compatibility, Improved Oral Function

Modern science and chemistry is amazing. I’ve touched on a few modern materials that have come into common use just in the last few years. You may hear about the new high strength ceramics, lithium disilicate or zirconia or the precision fit of milled dentures vs. traditionally cast and cured dentures, none of which was available to you until very recently. These materials are an improvement in every category except premium cosmetic esthetics. They are stronger, last longer, and cheaper than many hand built restoration material types like hand built glass-ceramics which still rank superior for premium cosmetic restorations like cosmetic porcelain veneers, but those are very expensive, built by a master ceramist/artist. You can bet that science and chemistry is working to compete or exceed in that category right now.

And Wait, That’s Not All

We can only guess at what is coming next but because digital allows for exponential change you can be sure that change is coming and it’s coming fast. With constant pressure on dentists to charge less for their services and with pressure on laboratories to cut pricing, under that pressure it has become essential for dental laboratories to compete to provide products Better, Faster and Cheaper. That pressure continues on to dental suppliers and manufacturers to in turn help maintain the lifestyles of dental technicians and to provide us with the new digital technology and materials to deliver in a very competitive world. I can’t wait to see what’s coming next.

About The Author

About The Author

After completing the Dental Technology course at the Southern California College of Medical and Dental Careers in 1973, Steve Killian began a ten year career in earnest as the Head Ceramist and General Manager of Jim Glidewell’s first satellite laboratory, Cal-West Dental Ceramics. In 1980 he became a CDT, receiving his 35 year pin at NADL’s Vision 21 Meeting in 2015. Steve opened his own lab in 1983, where he added a partner and brother, Greg Killian. Now as a 29 person lab in Irvine, CA, Killian Dental Ceramics, CDL offers products to please the most cosmetically driven patient and pricing to support any client’s budget. As the President, General Manager and Head Technician, Steve is in the perpetual pursuit of excellence, where change is the only constant while staying on the cutting edge of new technologies, processes, and services. Steve was on the NADL Board of Directors from 2010 – 2014 and is currently the Vice-Chair to the Foundation for Dental Laboratory Technology.

Steve, do you think there will be changes to dental interment’s being use today? I scanned through your article and learned you were talking about reconstruction, crowns and stuff like that. All is well here in Big Sky Country, just bough a Can Am ATV, can’t to get in the back country.

Amazing stuff

Jim

Hi Jim,

Thanks for your inquiry. Yes, the internet is a big part of digital dentistry because that is how the digital information travels between the dentist and the dental lab particularly when it comes to digital impressions or when one lab outsources or sends work to another lab that has better Cad Cam equipment. You will see more and more dentists converting the patient’s mouth into digital images that are easily transferred through the internet.

Your old buddy, Steve