The excitement surrounding Digital Denture Technology is escalating throughout our industry. This technology is evolving at a rapid rate. But without prosthodontic principles and a deep knowledge of the science behind the digital design aspect, case success will be compromised. For years the removable side of the business has been pushed to the background and not the forefront of dental technology. Yes we have had advances in materials such as denture teeth which look like natural teeth with anatomic tooth morphology including great wear resistance and with denture base materials with the right amount of high impact resistance in combination with the appropriate flexural strength. But not until recent years has the image and the focus of removable technology started to change. And I believe we can thank Digital technology for that.

So let’s dig deeper into the comparisons on both traditional (Analog) and Digital applications. Dental CAD/ CAM dates back to the mid 1980’s and has become the standard in the dental industry for treatments for crown & bridge and implants. Surprisingly, the majority of dentures are still made the traditional or analog way. Early adopters of digital denture technology have used new cutting edge CAD/CAM technology to revolutionize denture production. Research has shown that advanced 3D software systems provide increased accuracy, creates more comfortable dentures for patients, and allows the technician and clinician to complete a full denture case much faster with less chair time and adjustments.

But on the other hand, when we look at traditional denture techniques, the correct protocol with case planning, quality materials and the right processing systems also yield to the success of a denture case. Yes, once you learn all the software design applications and technologies with digital dentures, you will be able to produce a denture much faster with great accuracy. I do agree with other experts in the field that prior knowledge of removable science make it easier to learn software application and create the ability to design dentures correctly. The industry predicts tremendous growth on removables now through 2050 and experienced Denture Technicians are the guides for dentist and patient success in denture prosthesis. Professionals who understand dentures are the ones who understand smile design.

We must also keep in mind that the final prosthesis can only be as good as the information captured from the scan and this depends entirely on the professional recording the information. This brings us to the success rate of the intra-oral scanning of edentulous patients. Scanning is possible on fully edentulous cases, but is still not perfect. Additional steps must be taken and case selection is critical. The clinician may use an indelible pencil to help with stitching issues especially when scanning a particular arch where there are very few landmarks for reference. Edentulous arches with tissue texture and readable landmarks will make for a more successful scan. But the clinician must make sure to capture all anatomical landmarks.

We are continually getting closer with technology to make it possible for the successful scanning of the edentulous arch. With that said, there have been many clinicians who have been successful with scanning for complete dentures. The success of these scans stem from the right intra-oral scanner and the correct directional focus along the ridges and periphery when taking the scan.

When it comes to digital technology we need to utilize the same fundamental prosthodontic processes to make a digital denture as we have with analog. Also, the clinician still needs to communicate and provide the technician with the necessary information for an esthetic and functional case.

A successful digital denture case still requires attaining accuracy with impressions, maxillo-mandibular records, vertical dimension, and centric relation. While dental technicians still need to continue to analyze ridge relationships and then select appropriate anterior and posterior teeth for the desired occlusal scheme, many digital denture software platforms do this automatically. Many leading software systems now feature leading manufacturer tooth libraries and is compatible with a wide range of 3D printers and milling machines, giving the technician and clinician design and manufacturing options in a single, smooth workflow.

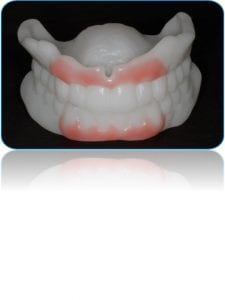

When designing dentures in the digital world many arch details can now be seen on a large screen which could not otherwise be detected previously (pic 1).

But are digital dentures truly digital for the clinician? Not if clinicians aren’t able to scan the maxillary and mandibular arches intra-orally. As I mentioned earlier, there are clinicians who are achieving this successfully, but most are still depending on capturing the appropriate information in an analog state. And what about workflow? With digital denture technology you are able to possibly cut down office visits to a four appointment workflow from a traditional five appointment workflow.

So instead of requiring the patient to come into the dental office for a separate custom tray impression and occlusal records, a visit can be eliminated by taking a functional border molded impression and bite registration at the same visit with a custom tray baseplate and a contoured wax rim attached to the baseplate (pic 2 and 3).

To go one step further, another appointment can be eliminated if a wash impression and a bite registration is taken at the first visit. The impression and bite registration can even be scanned at the dental office and the file emailed to the laboratory. This method cuts the workflow down to a three appointment denture.

With the digital denture workflow, a clinical try in will be performed utilizing a printed monolithic try in. This takes a little getting used to because now teeth cannot be moved or repositioned in wax in the dental office. But the teeth on the printed try in can be ground to compensate for occlusal errors and a new bite registration may also be taken. The clinician can even mark the midline with a sharpie if the midline is off and another wash impression can be taken inside the printed try-in if the try-in appear to be loose. All this information can be re-scanned back at the laboratory and merged with the original file with all the new modifications. At this point the final denture can be milled or printed or another printed try-in can be done.

I am used to making the traditional denture try-ins I work on look like the final denture finish (pic 4) by using various colored waxes to match the patient’s natural gingiva. So with the printed monolithic try-ins, I still try to make them look natural by adding these gingival shaded waxes (pic 5) to the contoured printed base.

Analog and digital technology work hand in hand with each other. There are features and benefits on both technologies. But I am finding that with digital technology on removables that the comfort level of the dentist is way up and the fit and function is significantly improved. Not to mention that if the patient loses or breaks and denture, another denture can be printed or milled very quickly because of the file on record.

Analog and digital technology work hand in hand with each other. There are features and benefits on both technologies. But I am finding that with digital technology on removables that the comfort level of the dentist is way up and the fit and function is significantly improved. Not to mention that if the patient loses or breaks and denture, another denture can be printed or milled very quickly because of the file on record.

Developments in software and improved manufacturing methods present a great opportunity to shift the experienced denture technician’s expertise to a digital platform. Also, advanced CAD/CAM denture software now delivers razor-sharp accuracy with reproducible results for dentures with better comfort, fit, esthetics and strength – and at a much lower cost than your conventional denture workflow.

About the Author:

Dennis Urban, CDT brings 40+ years of dental technology field experience including lab management, technical training, sales and marketing, product development, and quality assurance. In addition to being a seasoned dental lab manager, Dennis has been an eminent lecturer worldwide since 1985. His lectures and trainings span many areas of dental technology, to include: denture set-ups, digital technology, denture processing, lab management, implant overdentures and bar design protocol, all on 4 and 6 case planning, chairside conversions, shade communication, occlusion and soft liners. His technical articles have been published in publications across the US, Canada and Europe. Dennis Urban is the current Chair of The National Board of Certification In Dental Technology, and is Vice President of Education and Training for Dental Services Group (DSG).

Ads Dental Lab Co., Ltd was established in 2004. We are a family owned group of dental laboratories, providing you with a full range of services, including ceramics/crown & bridge.

The technology regarding health treatments is changing day by day. This changing technology has made a lot of things easier. Now, longer time for treatments is not taken as they provide quick treatments and better results as well. Keep sharing this more and more!

Dentist in Longmont CO

Thank you for sharing the information and It was very useful for everyone. For more details visit https://maaent.com/dental/index.html