In the realm of global dentistry, health and safety processes and procedures have always been stringently regulated. Protec Dental Laboratories LTD, Vancouver, BC, Canada, places great emphasis in following internal and external regulatory guidelines that are predominantly outlined by both the Provincial Ministry of Health and College of Dental Technicians of BC. Pre COVID-19, disinfection processes have always been mandated across the dental industry. During the time of COVID-19 closures (March–May), new information relating to sanitization and infection control began to materialize. It was inevitable that the existing regulations would be enhanced, and, in anticipation, we began a methodical approach to prepare for reopening. The most obvious questions were: What will we need to change? What new procedures will we implement? How are we going to achieve it?

In the realm of global dentistry, health and safety processes and procedures have always been stringently regulated. Protec Dental Laboratories LTD, Vancouver, BC, Canada, places great emphasis in following internal and external regulatory guidelines that are predominantly outlined by both the Provincial Ministry of Health and College of Dental Technicians of BC. Pre COVID-19, disinfection processes have always been mandated across the dental industry. During the time of COVID-19 closures (March–May), new information relating to sanitization and infection control began to materialize. It was inevitable that the existing regulations would be enhanced, and, in anticipation, we began a methodical approach to prepare for reopening. The most obvious questions were: What will we need to change? What new procedures will we implement? How are we going to achieve it?

How Ideas Transitioned to Strategic Planning

Understanding the publicized intricacies of the COVID-19 pandemic, including exposure and transmission, were vital. Prevention and control became the highest priority in order to adhere to the ever-changing worldwide protocols and, to save lives. This remains every citizen’s and corporation’s responsibility. Our leaders at Protec Dental Laboratories wholeheartedly embraced this ideology and moved quickly to incorporate it into the strategic goals, ensuring that it became ingrained into every employee’s daily workflow.

Prioritizing Health & Safety

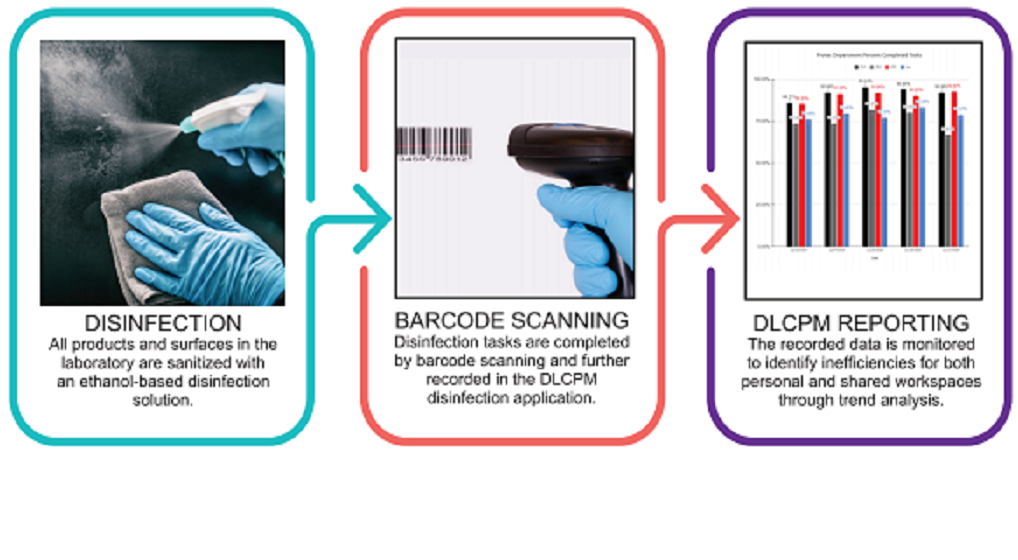

During an early roundtable discussion, the decision was made to revamp our existing disinfection protocol. The main challenge would be to systematically achieve this with 215 employees operating across four buildings. We determined that there were approximately 800 required cleaning and disinfecting sanitization tasks within a specified daily frequency. Enhanced infection protocols directed our focus on the necessity to implement a robust barcode scanning system. This system would deliver efficiency and accountability through tracking and data analytics, specifically for the disinfection of personal and shared workspaces. Each area was assigned a unique name and barcode with a detailed description of the cleaning expectations. Magic Touch Software Lab Management System (DLCPM)’s Disinfection Procedure Feature was utilized and customized within our trusted CRM platform to deliver all the features we had aspired to. Further enhancements to this revamped sanitization workflow included plexiglass dividers, mandatory PPE, 2-meter social distancing, and screening of all employees, patients and visitors. Additionally, we have adapted an environmentally conscious ionization process that is distributed through fogging. It became our prime concern to create the safest environment for our most valued assets: our employees! Business strategies have continued to evolve including the realization that the aftermath of COVID-19 would linger for some time, centering future plans around the long term. Managing the Workflow

Managing the Workflow

Hon, our Health & Safety Officer with an education background from The University of British Columbia, was appointed to lead our broadened infection control team and was promoted accordingly. Hon maintains an aptitude for growth and development and works closely with our senior management team. Through closeknit collaboration and teamwork, a streamlined workflow including training, learning resources, application and close monitoring has been achieved. Our digital infection control program has become a great success; we continue to adapt and navigate through the hurdles of COVID-19, while striving for a brighter tomorrow.

About the Author

Kimara K. Ackerley is the Project Manager at Protec Dental Laboratories LTD, Vancouver, BC, Canada. Established in 1973, Protec Dental Laboratories LTD has grown to become one of Canada’s largest full-service dental labs. Protec takes great pride in its Canadian heritage while embracing a diverse team of employees from every corner of the world. It is a collaboration that continues to transform the art and science of crafting dental appliances into a highly precise and ultraefficient process, including the integration of new digital technologies.

This blog is helpful.