It wasn’t so long ago (2004 to be exact) when there was only one zirconia available on the dental market. Now there are dozens! While this is a typical evolution for a material substitution, the number of options makes deciding which one to use difficult.

The original zirconia was chalky white and substituted for the alloy portion of a porcelain-fused-to-metal restoration. In 2009, the introduction of monolithic zirconia eliminated the need for porcelain. From there, the number of zirconia options just kept growing, offering different chemistries, different strengths, and different coloring schemes. This leads to questions on how to decide which supplier and which material to use.

To begin, as with any other critical supplier decision, the lab should work with a company that is reliable and can provide support for the products they sell. Unfortunately, the ISO standard for zirconia (ISO 6872:2015) is of no help in discriminating between sub-par and good materials. The ISO standard does not address Thoria radioactivity, which is present in the original zircon mineral. Also, the standard provides little guidance on the strength of zirconia restorations. The values published are seen by most reliable companies to be insufficient. This means that a manufacturer could have a zirconia product placed on the market with a 510k and the users would still not be certain as to its strength or radioactive properties.

Some of the incidents with zirconia materials that we are aware of include:

- No radioactivity reports of the zirconia powder from some powder suppliers.

- Inconsistent strength and/or translucency from lot to lot.

- Poor compositional control.

- Even insects in the powder!

But because of our tight supplier quality control, such materials have never been used by Argen. All materials will evolve over time and zirconia is no different. Although the majority of published clinical reports on dental zirconia are retrospective, the results have been extremely good on all fronts: esthetics, strength and biocompatibility. Zirconia will continue to be the material of choice for dental prosthetics at least for the next decade, keeping in mind that more zirconia compositions will be introduced and our most difficult challenge will be to educate the dentist on the features and benefits of a chosen product.

Once the supplier has been decided, it is now time to consider the material selection. How you choose to color your zirconia plays a crucial role in determining what material you need to use for your application. We will discuss the coloring schemes since this decision impacts both the esthetics of the zirconia and the costs of carrying the inventory.

There are three basic ways of attaining the proper shade: 1) start with a white zirconia disc and use coloring liquids to attain the desired shade; 2) use preshaded zirconia discs; or 3) use multi-layer zirconia discs.

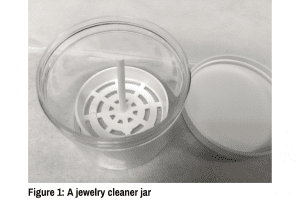

- Water based coloring liquids provide the most control and the easiest way to individualize a case. The zirconia disc inventory costs are low but the results may be inconsistent. The shade will be dependent upon the amount of coloring liquid absorbed and the type of coloring liquids used. Also the quantity of yttria in the zirconia may require a different coloring solution. As the amount of yttria increases the amount of coloring elements must also increase. This is why there are different solutions for high translucency and super translucency zirconia. For a case that consists of several restorations using a jewelry cleaner jar (as shown in Figure 1) full immersion of the units in the coloring liquid ensures that the time in the liquid is the same for all units. It is important for the units to be dried prior to sintering. This is best done by air drying. Drying the units too fast may leave a frosty appearance on some zirconia compositions.

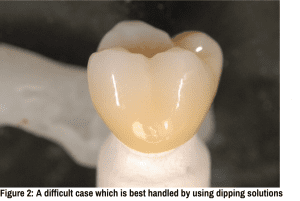

Figure 2 shows a difficult case which is best handed by using dipping solutions. This is a custom shade with a modified incisal, longer ‘enamel’ layer and intrinsic characterization. The unit has been glazed only with no external stain.

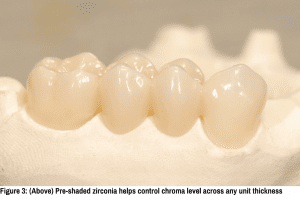

- Pre-shaded zirconia helps control chroma level across any unit thickness as shown in Figure 3. The major question with pre-shaded discs is “does the zirconia manufacturer have the same color understanding as you do?” Since we all see color differently, the concept of the shade A2 can vary. Using pre-shaded discs increases the inventory costs but this is more than compensated for by the consistent results.

- Multilayer discs have different chroma levels increasing from the incisial to the gingival layer emulating the natural color transition found in teeth (Fig. 4). As with all zirconia, the color cannot be seen until the material is sintered so nesting becomes very important. Although the inventory costs are high compared to just the white discs, the results can be outstanding. So which type is right for your lab? The options will only keep increasing in the future.

Reprinted with permission from the March 2020 Issue of the Journal of Dental Technology (JDT)

About the Author:

Paul Cascone, Senior Vice-President of Research & Development, The Argen Corporation

Paul Cascone, Senior Vice-President of Research & Development, The Argen Corporation

Paul is the Senior VP of Research and Development at Argen, where he has been responsible for the development of alloy and ceramic products for the Argen Corporation since 1996. Along with forty years of experience in the research and development of dental products, Paul has published articles and book chapters in dental, metallurgical and ceramic publications. He also has published worldwide patents and gives seminars around the globe.

Paul received a Bachelor of Engineering in Metallurgical Engineering from New York University, his Masters of Science in Ceramic Science from Rutgers University and was a student at Harvard University’s Advanced Management Program.